- November 26, 2025

- CRM-Masters

-

- 0

Client Profile

The client is a leading Industrial Machinery Installation company specializing in end-to-end setup of heavy manufacturing equipment, assembly line systems, and automated production machinery across multiple sectors such as Automotive, Pharmaceuticals, Textiles, and FMCG.

With operations across India and the Middle East, the company serves large factories and production units, managing the entire lifecycle—from equipment delivery and installation to testing, commissioning, and ongoing maintenance.

Before implementing Zoho, the company relied heavily on manual processes to track projects, customer requests, technician schedules, spare parts, and post-installation service tasks. Data existed in spreadsheets, WhatsApp groups, and shared drives, making it difficult to track progress, ensure accountability, and meet client deadlines.

India & Middle East

B2B (Business to Business)

Manufacturing & Industrial – Heavy Machinery Installation

Technology Used

The objective was to digitize the company’s complete machinery installation workflow. Their goals included:

- Centralizing lead and project-related information

- Tracking installation progress and technician activities

- Managing service visits, AMC contracts, and spare parts

- Improving collaboration between sales, service, and installation teams

- Enhancing customer satisfaction through real-time updates

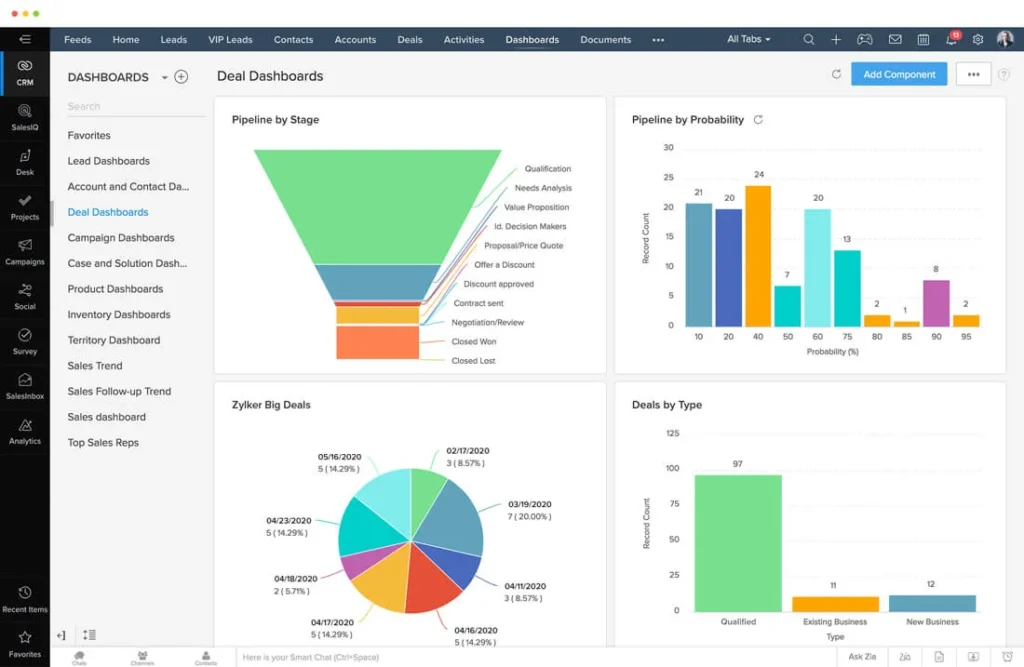

- CRM for lead and customer lifecycle management

- Project tracking for machinery installation, testing, and commissioning

- Service management for preventive and corrective maintenance

- Mobile accessibility for field technicians

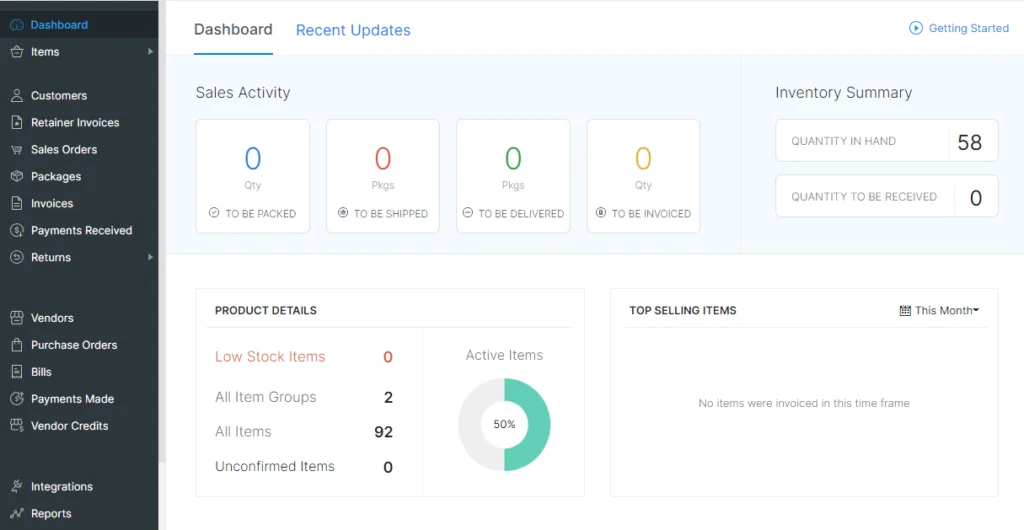

- Inventory tracking for machinery components and spare parts

- Real-time dashboards for management

Challenges Faced by Industrial Machinery Installation Companies

Fragmented Data & Manual Processes

Lead information, installation details, and service requests were scattered across multiple non-integrated tools, increasing the risk of data loss and delayed response.

Unstructured Project Tracking

Installation timelines, technician tasks, and commissioning phases were recorded manually, making it difficult to measure progress or meet deadlines.

Service & AMC Management Bottlenecks

AMC schedules, warranty calls, and service histories were not documented systematically, resulting in missed visits and customer dissatisfaction.

Spare Parts & Inventory Visibility Issues

Spare parts availability was difficult to track, causing delays during installation or servicing due to lack of real-time stock visibility.

Technician Coordination Problems

Technicians lacked a unified mobile app to log activities, upload reports, or track customer visits, leading to inconsistent documentation.

Limited Management Insights

Managers had limited visibility into installation progress, technician performance, and profitability.

Our Solution for the Industrial Machinery Installation Company

Zoho CRM unified all customer data, inquiry details, proposal stages, and project approvals. Automated lead routing ensured that inquiries were assigned promptly based on region, industry, and equipment type.

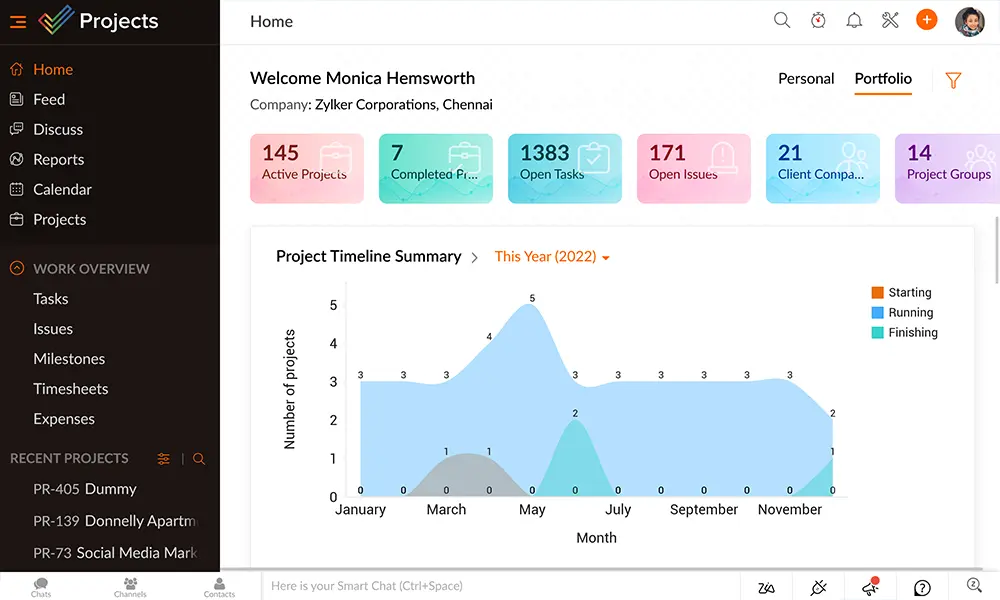

Installation workflows were digitized using Zoho Projects. Each project included:

- Delivery confirmation

- Installation schedule

- Testing and calibration

- Commissioning

- Handover documentation

Blueprints ensured every phase was completed and approved systematically.

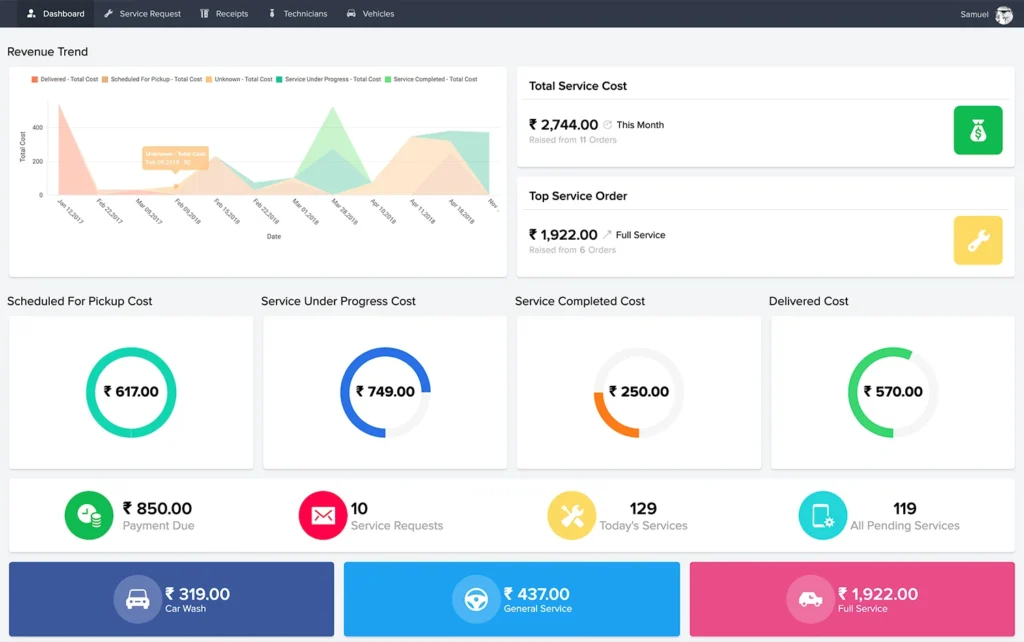

A custom Field Service Management App was built to:

- Track technician schedules

- Record site visits

- Upload installation photos and testing reports

- Manage spare parts consumption

- Capture customer signatures digitally

Integration with CRM and Creator enabled complete visibility of machinery parts, consumables, and replacement components. Automated alerts notified procurement teams about low stock levels.

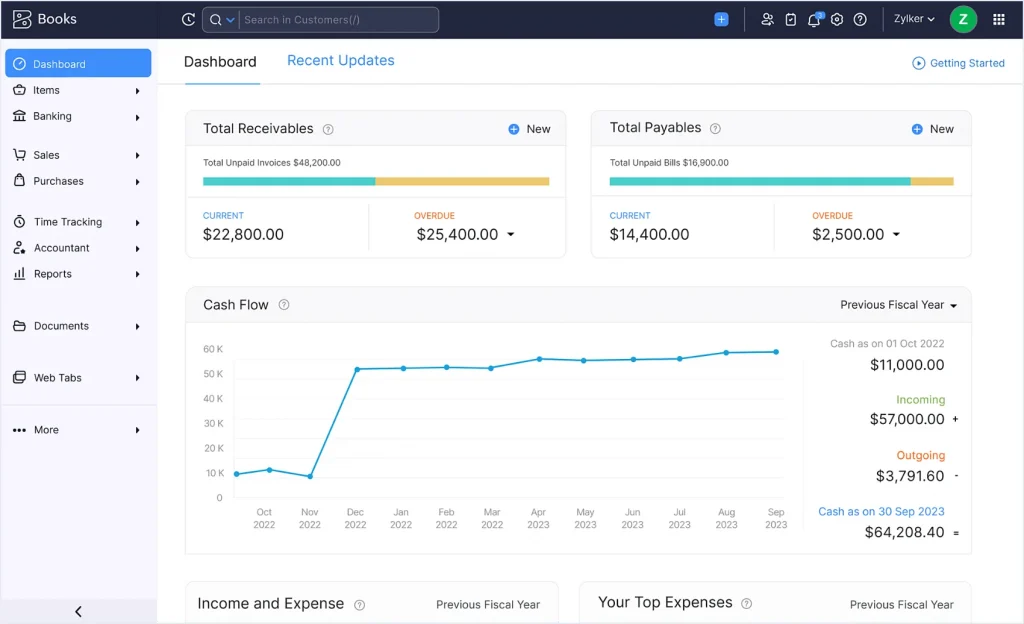

Invoices for installation charges, AMCs, spare parts, and additional services were automated through Zoho Books. The system also tracked payables and receivables linked to each project.

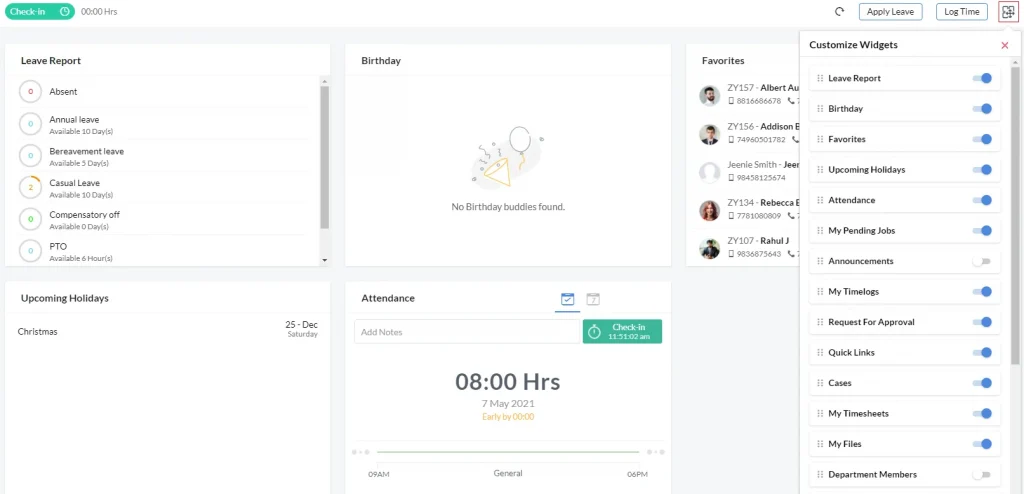

Technician attendance, timesheets, and field check-ins were digitized. GPS tracking helped validate on-site hours and ensure work transparency.

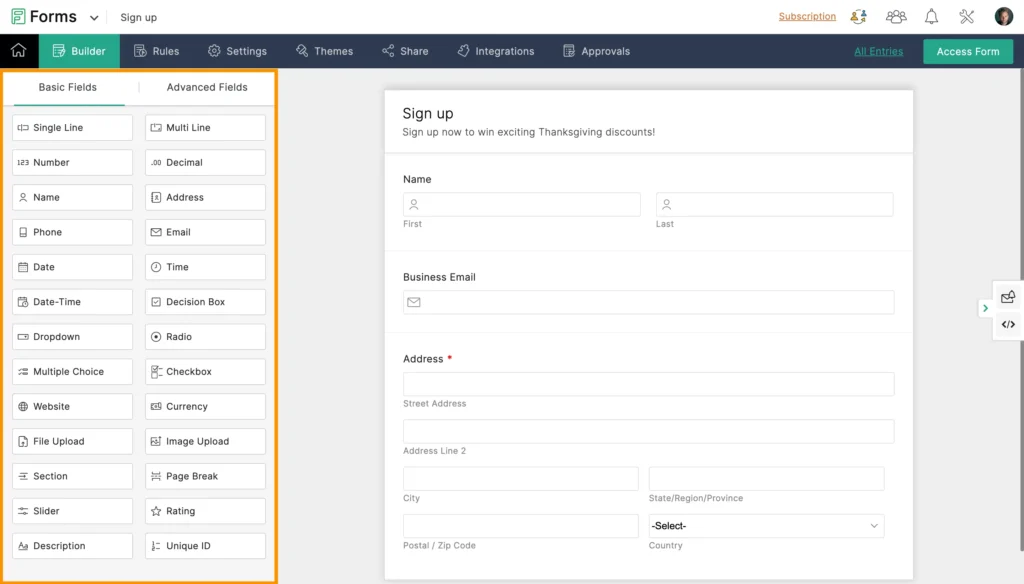

Customized digital forms captured:

- Installation checklists

- Maintenance reports

- Warranty claim records

- Commissioning certificates

Forms were automatically attached to CRM records for audit readiness.

Results Achieved with Zoho

Key Outcomes Included

Efficient Project Delivery

Digitized workflows and milestone tracking ensured on-time installation and faster commissioning.

Improved Service Operations

AMC schedules, service calls, and renewal reminders were automated, improving customer satisfaction and reducing downtime for clients.

Increased Technician Productivity

Mobile apps empowered technicians with real-time data access, resulting in better documentation and faster issue resolution.

Enhanced Spare Parts Management

Inventory visibility reduced delays during installations and service calls, improving operational efficiency.

Financial Transparency

Automated invoicing and expense tracking improved cash flow and reduced manual errors

Performance Improvements

Improvement in Installation Tracking Accuracy

Faster AMC and Service Visit Scheduling

Increase in Technician Productivity

Reduction in Manual Documentation

Faster Invoice Generation & Payment Cycles

Real-Time Inventory Visibility

About CRM Masters Infotech

(ISO: 9001-2015 & ISO 27001:2022) Certified Company.

CRM Masters Infotech, as a Zoho Premium Partner, brings more than 10 years of experience in delivering customized Zoho solutions for manufacturing, industrial, and engineering companies.

With 4000+ successful projects across 30+ countries, we help organizations automate their operations, improve field service efficiency, and enhance customer management through powerful, integrated Zoho applications.

Looking for Zoho implementation?

Talk to our experts today—trusted by businesses across the global.